5 Ways the Right Biotech OEM Partner Can Make or Break Your Success

Learn the five key factors biotech companies should evaluate when choosing an OEM partner: technical knowledge, customization, compliance, scalability, and support.

Table of Contents

Why technical depth, flexibility, compliance, and ongoing support are non-negotiable for successful partnerships

Choosing the right OEM partner is one of the most high-stakes decisions biopharma companies face. From the earliest prototypes to production, seamless development depends on more than a supplier’s catalog—it hinges on their process knowledge, engineering flexibility, and a long-term vision aligned with yours.

Todd Upton, Director of OEM and Service at AES, shares key lessons from his work with companies across the biotech landscape. Drawing on his team’s experience building custom systems for everything from stem cell culture to engineered proteins, Todd helps illuminate what separates a capable vendor from a true partner. This article explores the five essential criteria that biotech companies should consider when selecting an OEM partner.

1. Deep biotech process expertise

Biotech manufacturing isn’t plug-and-play. Systems need to reflect the unique physical, regulatory, and operational demands of each process. “Deep technical knowledge allows the OEM partner to understand the critical nuances needed to design equipment for complex processes,” Todd explains. “This is especially true in areas like stem cell culture or engineered proteins.”

These processes require highly sensitive control systems, precise environmental parameters, and compatibility with rapidly evolving materials and technologies. Without biotech-specific expertise, an OEM risks delivering solutions that introduce friction, fail audits, or require extensive redesigns to work effectively.

Clients often turn to AES with questions about cGMP requirements, 21 CFR Part 11 compliance, and integrating components like Watson Marlow pumps or Raman spectrometers. Questions our team answers with real-world context drawn from previous builds.”. Todd’s team not only answers these questions but contextualizes them with examples from past builds, offering real-world validation without compromising client confidentiality. This level of detail and transparency builds trust and reveals technical depth.

2. Custom-engineered solutions

Every biotech process has its own parameters, and off-the-shelf equipment rarely fits all the pieces together. “The risk of a one-size-fits-all approach is that it doesn’t optimally meet the client’s process requirements,” says Todd. “You might end up with the wrong flow rates or control limitations because the equipment wasn’t purpose-built.”

Customization isn’t a luxury—it’s essential to performance. Todd explains that process-specific needs often involve advanced operations, such as perfusion, capacitance, or spectroscopy-based control. AES’s engineering approach is grounded in adaptability. Whether it’s modifying a bio controller for higher oxygenation levels in stem cell culture or integrating proprietary client technology, AES builds with the process in mind.

“We had to create a highly specific biocontroller to match one client’s unique stem cell platform—that kind of customization made the difference in their ability to scale successfully.”

Todd Upton

Director of OEM & Service

These custom builds are a core part of AES’s offering. Rather than forcing clients to compromise their process for the sake of the equipment, AES engineers solutions that enhance process fidelity and future scalability.

3. Built-in scalability to GMP

One of the biggest risks in equipment design is underestimating the effort required to scale. Many biotech firms approach AES with a functioning R&D setup but no roadmap for GMP production. “The requirements for research labs versus regulated production environments are vastly different,” Todd says. “Traceability, automation layers, cleaning protocols—all of these impact the equipment design.”

“Traceability, automation layers, cleaning protocols—all of these impact the equipment design.”

Todd Upton

Director of OEM & Service

AES bridges the R&D-to-GMP gap from day one. Without accounting for these differences early on, companies often face costly re-engineering or tech transfer delays. AES avoids this by bringing GMP thinking into every phase, even when working on early-stage concepts. They anticipate what regulatory scale-up will require and design accordingly, reducing future risk.

Todd recalls multiple cases where this foresight prevented months of delays and rework. By involving AES early, clients not only receive R&D tools, but they also gain a long-term equipment strategy.

4. Regulatory documentation support

Regulatory approval is a critical milestone, and documentation can be the difference between fast-tracking and failing to meet deadlines. That’s why companies must ensure their OEM partner operates with certified quality systems and structured engineering processes.

Todd explains, “We follow a GMP-compliant systems engineering process that produces the right documentation at every step—from design drawings and URS to IQ/OQ protocols.” AES also holds relevant ISO certifications that clients and regulators expect from top-tier OEM vendors.

This comprehensive documentation not only supports compliance audits but also facilitates smoother tech transfer between geographies, contract development and manufacturing organizations (CDMOs), or departments. Clients benefit from less backtracking, fewer surprises, and faster regulatory progress.

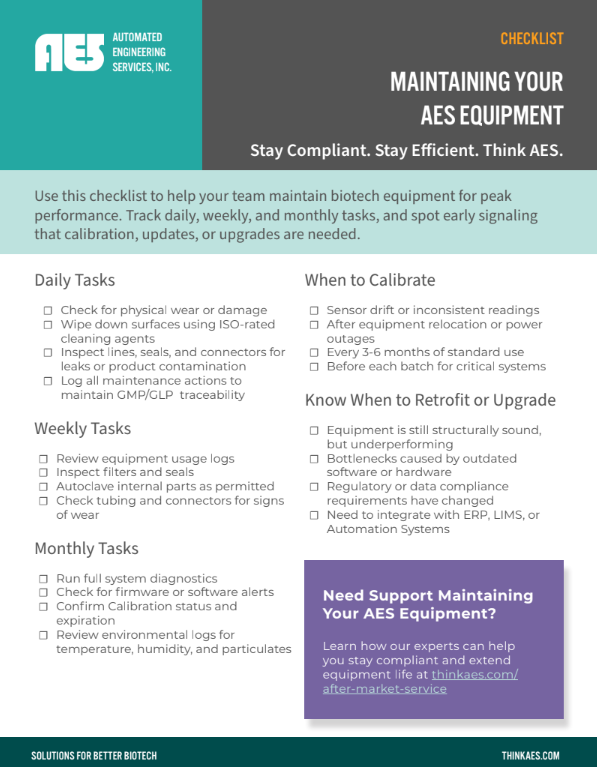

5. Reliable aftermarket services

The sale doesn’t end at delivery, and neither should the relationship. Yet many OEMs treat post-sale support as an afterthought. According to Todd, this is a mistake that can carry serious consequences. “Clients often underestimate the complexity of their systems and the importance of ensuring optimal operation over time,” he notes. “Without proper support, you’re looking at reduced efficiency or obsolete equipment.”

Lack of support can mean unexpected downtime, lost yield, and unexpected costs. AES prioritizes availability, firmware and software updates, and fast issue resolution. Their commitment doesn’t wane once the equipment is installed. Todd emphasizes that their support team’s technical depth and quick turnaround are what long-term clients appreciate most.

“They value our detailed record keeping, fast response times, and internal expertise. We’re not just fixing problems—we’re invested in their success,” he says.

Why These Considerations Matter

Choosing an OEM partner in biotech is not just a procurement decision—it’s a strategic investment in your ability to scale, comply, and innovate. From understanding process complexity to offering lifecycle support, the right partner can reduce delays, eliminate rework, and improve operational outcomes.

Companies that prioritize these five factors—technical expertise, customization, scalability, compliance, and aftermarket services—position themselves for smoother growth and fewer setbacks.

AES doesn’t just manufacture equipment. It brings clarity, structure, and shared commitment to every project.

Let’s design equipment that works for your process, not the other way around.

Our OEM experts build GMP-compliant solutions with technical depth, scalability, and lifecycle support—customized to your biotech process from R&D to regulated production.