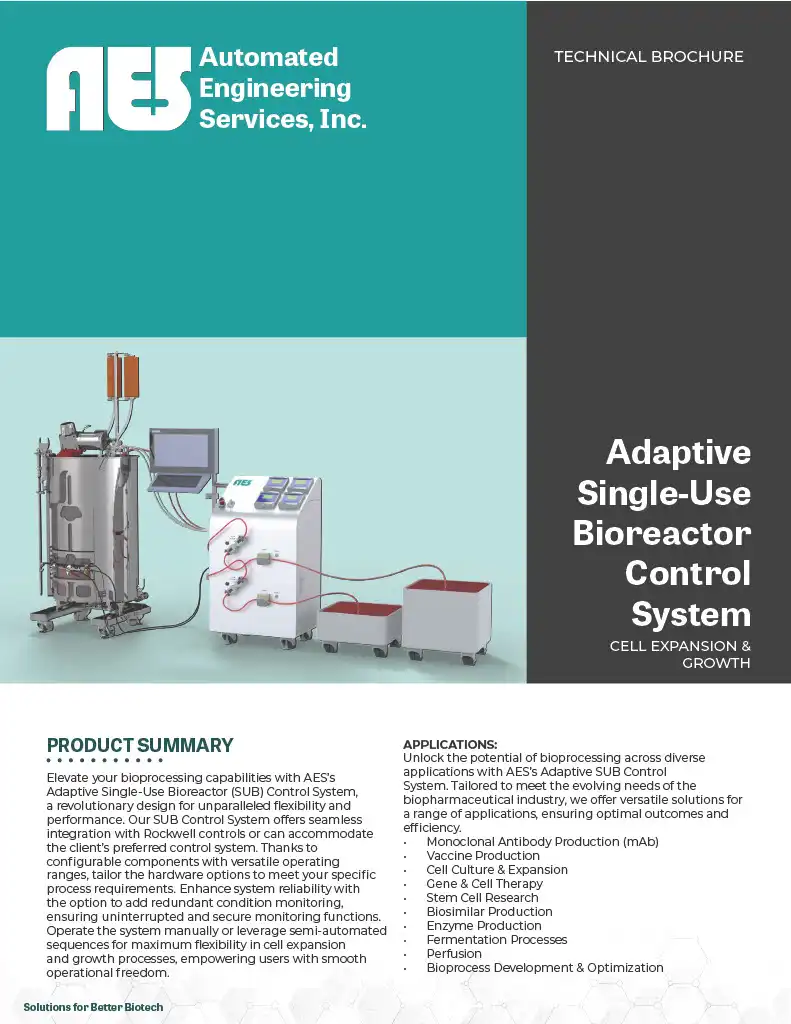

AES Single-Use Bioreactor Control Systems

Adaptive SUB Control System

The Adaptive SUB Control System is a state-of-the-art solution that elevates cell culture processes, particularly in single-use bioreactor applications. With advanced control capabilities for liquid management, gas flow, temperature, and real-time monitoring, this system ensures exceptional precision and efficiency. Its flexible design allows seamless integration with your preferred control systems and vessels, maximizing adaptability for diverse bioprocessing needs. The optional redundant condition monitoring enhances system reliability, ensuring uninterrupted operations. Tailored for various applications, including monoclonal antibody production, cell therapy, and bioprocess development, the Adaptive SUB Control System is a robust and high-performance platform for the evolving biopharmaceutical industry.

Benefits of the Adaptive SUB Control System

Achieve Seamless Scale-up

The Adaptive SUB Control System supports working volumes from 50L to 500L, enabling you to expand capacity without redesigning your process. Eliminate costly system transitions as your production grows—maintaining consistency from pilot to full-scale GMP manufacturing.

Reduce capital costs and launch faster

Designed for efficiency and adaptability, this system minimizes upfront investment and simplifies facility start-up—so you can move from design to validation and into production quickly, without compromising compliance.

Adapt to your infrastructure with broad compatibility

The system integrates easily with leading platforms like Rockwell and DeltaV, and accommodates vessels such as Thermo Fisher HyPerforma™ or your preferred options—supporting evolving process demands across multiple facilities or product lines.

Gain precise, real-time control over your entire bioprocess

With advanced automation, intuitive HMI, and reliable gas, liquid, and temperature control subsystems, the Adaptive SUB Control System ensures optimal conditions for cell growth, expansion, and product consistency—every step of the way.

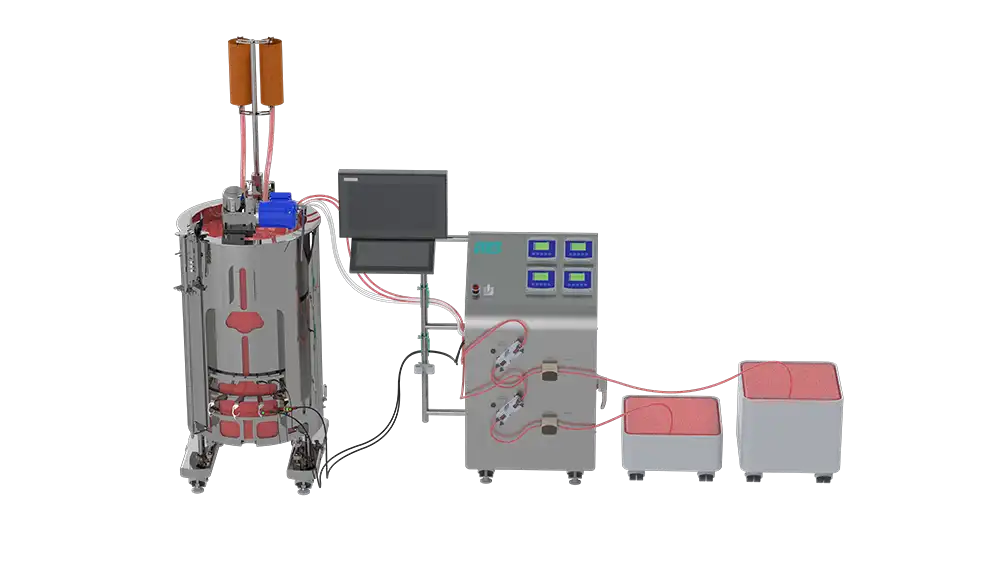

Adaptive Single-Use Bioreator Control System

Details & Technical Data

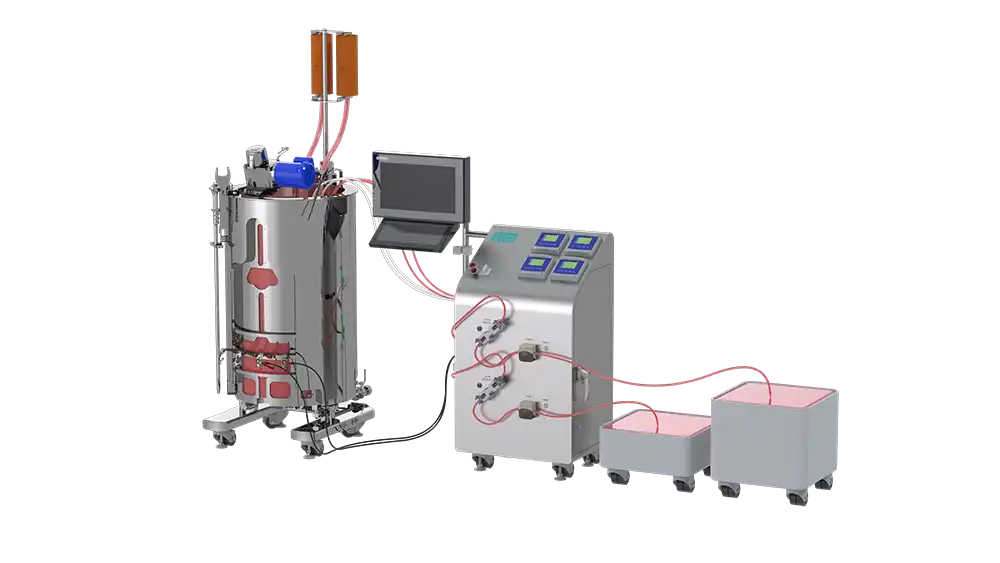

The Adaptive SUB Control System offers a highly advanced environment for optimizing cell culture processes, particularly in single-use bioreactor applications. Engineered with cutting-edge features for precise control over critical parameters, including liquid management, gas flow, temperature, and real-time monitoring, this system is designed to meet the stringent demands of modern bioprocessing. Its versatile and modular design allows seamless integration with various control systems and bioreactor vessels, maximizing adaptability and scalability from process development to full-scale manufacturing. Ideal for a wide range of applications, including monoclonal antibody production, cell therapy, and bioprocess development, the Adaptive SUB Control System ensures reliable, high-performance operation fully compliant with industry standards and regulations.

- Vessel Compatibility: Thermo Fisher HyPerforma™ or preferred vessel of your choice

- Gas Control: 5 Mass Flow Controllers (MFCs) for precise regulation of CCA, O2, CO2, and N2, with user-configurable flow rates from 0.003 – 50 SLPM

- Temperature Control Range: 5°C to 40°C with ±0.1°C accuracy, supported by the auxiliary Temperature Control Unit (TCU)

- Weight Measurement: Integrated load cells for real-time monitoring with optional media scales for custom bioprocessing needs

- Liquid Control: Dual peristaltic flip-top pump heads with flow meters for accurate liquid handling and measurement

- Enclosure Dimensions: 43.18 cm x 66.04 cm x 154.94 cm (17 in x 26 in x 61 in)

- Power Requirements: 120 – 230 VAC, 50/60 Hz, 1200 Watts

- Automation & Control: Standard Rockwell™ software with Ethernet/IP or Modbus RS485 communication

More details are available in the technical brochure.

The Adaptive SUB Control System is engineered to meet the stringent requirements of regulated environments. It is GMP compliant and can be configured to support 21 CFR Part 11 compliance, ensuring adherence to electronic records and signatures industry standards.

Adaptive Single-Use Bioreator Control System

(2) Integrated Pumps

(2) Flow Sensors

Side Panel with Connection Access for:

- Pressure

- pH

- DO

- Vent Filter Heater

- Temperature

- Sparge & Overlay

E-Stop Button & On/Off Switch

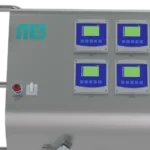

HMI

(2) pH & (2) DO Transmitters

Main Power Supply

Compatible Single-Use Bioreactor Vessel

Bioreactor Control Panel

(2) Integrated Pumps

(2) Flow Sensors

Side Panel with Connection Access for:

- Pressure

- pH

- DO

- Vent Filter Heater

- Temperature

- Sparge & Overlay

E-Stop Button & On/Off Switch

HMI

(2) pH & (2) DO Transmitters

Main Power Supply

Compatible

Single-Use

Bioreactor Vessel

Bioreactor Control Panel

Why Choose AES for Your Single-Use Bioreactor Control System?

Customizable for Your Bioprocess Needs

The SUB Control System can be tailored to meet the specific requirements of your bioprocess. Whether you need custom sizes, configurations, or features, we work closely with you to ensure this rocking bioreactor system aligns with your needs.

Seamless Integration for Your Lab or Facility

The SUB Control System is designed for seamless integration with your DCS. This compatibility allows for easy connection and communication with existing automation and control systems, enabling centralized monitoring and control of your operations.

Aftermarket Services & Training

Comprehensive aftermarket services and training is available to ensure you get the most out of your SUB Control System. Our team provides ongoing support, maintenance, and training to keep your operations running efficiently and effectively.

Fabricated in the USA

All SUB Control Systems are manufactured in the USA, adhering to the highest standards of quality and precision. This ensures reliability and consistency in every unit, providing you with a dependable solution for your bioprocess needs.

Adaptive SUB Control System Applications

Cell Culture

- mAb Production

- Vaccine Production

- Recombinant Proteins

- Biosimilars

- Cell-Based Meat

Gene Therapy

- AV

- Gene Replacement

- Gene Editing

- Oncolytic Viruses

Cell Therapy

- CAR-T Therapy

- iPSC

- MSC

- Immune Cell Expansion

Fermentation

- Bacterial Cultures

- Yeast Cultures

- Enzyme Fermentation

- Microbial Fermentation

Bioprocessing & Manufacturing

- Media & Buffer Prep

- Upstream Processing

- Process Development

Frequently Asked Questions

Below are answers to some of our most common questions about our Adaptive SUB Control System. Whether you’re looking for detailed specifications, customization options, or insights into how the system fits your process, we’ve got you covered. If you have any further questions, please don’t hesitate to contact our team.

The Adaptive SUB Control System is designed to work seamlessly with Thermo Fisher HyPerforma™ vessels. However, we know each process is unique, so our system can easily be customized to work with other bioreactor vessels that fit your specific requirements. Let us know what you need, and we’ll make it work!

Absolutely! We understand that every bioprocess is different, and that’s why the Adaptive SUB Control System is highly customizable. Our team will work closely with you to tailor the hardware options and control settings to meet the specific needs of your cell culture or expansion process.

Absolutely. The SUB Control System integrates with Rockwell as a standard offering. However, our engineering team can customize the integration to seamlessly work with your preferred DCS, ensuring compatibility and streamlined operation within your existing automation infrastructure.

Our system takes the guesswork out of managing key parameters like liquid handling, gas flow, temperature, and weight. With real-time monitoring and precise control, you’ll have confidence that your cell growth and expansion processes are optimized every step of the way. We’re here to help you get the most reliable performance out of your system.

Yes, it does! We offer optional redundant condition monitoring to give you extra peace of mind. This means that even if something unexpected happens, your system will continue running smoothly, helping you avoid costly downtime and ensuring reliable performance.

Certainly! At AES, we conduct rigorous Factory Acceptance Testing (FAT) to guarantee that all equipment meets our stringent quality standards before it leaves our facility. In addition to FAT, our dedicated Global Service Team can oversee Site Acceptance Testing (SAT) to ensure seamless installation and operation at your site. For more detailed information, please visit our Aftermarket Service page.

Yes, in addition to detailed user manuals, we can provide comprehensive operator training sessions. Our training ensures your team can confidently operate and maintain our equipment, maximizing its performance and longevity.

Yes, we do. Our Global Service Team is unwaveringly dedicated to providing comprehensive aftermarket support to ensure your equipment continues to operate at peak performance. For any issues that cannot be resolved remotely, we guarantee on-site arrival within 48 hours. For more details, please visit our Aftermarket Service page.

Lead times vary depending on the complexity and customization requirements of the equipment. Our sales team can provide specific lead time estimates based on your project timeline and needs.

We can provide references upon request. These documents showcase our successful collaborations and the positive impact of our solutions on our clients’ operations.

Get a SUB Control System that Meets Your Specific Bioprocess Today!