AES Bioprocess Controllers

Basic Fermentation Benchtop Bioprocess Controller

The Basic Fermentation Bioprocess Controller (BPC) is an innovative benchtop solution designed to optimize mammalian cell culture with precision and efficiency. This controller offers comprehensive control over critical parameters such as pH, dissolved oxygen (DO), temperature, and agitation, ensuring optimal growth conditions for microbial fermentation and other bioprocess application. With its compact, ergonomic design, customizable hardware, and flexible operating ranges, the BPC is ideal for research, process development, and supporting scale-up processes. It is aligned with GMP standards and 21 CFR Part 11 compliance, providing a reliable and high-performance platform for biopharmaceutical applications.

Benefits of the Basic Fermentation Benchtop Bioprocess Controller

Optimized Fermentation Control

Dial in ideal fermentation conditions with precise control over pH, dissolved oxygen, temperature, and agitation—empowering you to maximize microbial growth, enhance product yield, and maintain reproducibility across batches.

Flexible Integration

Plug into your preferred automation strategy with seamless integration into Rockwell platforms or stand-alone and DCS configurations—enabling you to build a fermentation system that aligns with your facility’s infrastructure and operational goals.

Versatile Vessel Compatibility

Work your way with support for both single-use and reusable vessels. Whether you need quick turnarounds or validated, sterilizable setups, this system adapts to your process and sterilization protocols without compromise.

Enhanced Process Control

Gain tighter control over your fermentation process with real-time monitoring and intelligent automation—reducing variability, streamlining operations, and boosting batch-to-batch consistency.

Scalability

From early-stage development to pilot-scale production, the system supports working volumes from 2L to 15L—giving you a flexible platform for scaling up processes without switching equipment.

Basic Fermentation Bioprocess Controller

Details & Technical Data

The Basic Fermentation Bioprocess Controller (BPC) provides a precisely controlled environment crucial for optimizing microbial fermentation processes. Its flexible design accommodates various fermentation applications, offering precise control over critical parameters such as pH, dissolved oxygen, temperature, and agitation. Compatible with single-use and multi-use vessels, the BPC is well-suited for microbial fermentation, enzyme production, and other biopharmaceutical applications. With manual or semi-automated operation options, advanced process monitoring, and remote control capabilities, the Basic Fermentation BPC ensures consistent, high-quality results across diverse fermentation workflows.

- Working Volume Capacity: 2L to 15L

- pH Control: 2 – 12 pH

- Dissolved Oxygen (DO) Control: 0 – 100% Air Saturation ± 1% reading

- Temperature Control Range: 0 – 100°C ± 0.15°C

- Motor Speed Range: 0 – 600 RPM

- Agitation Direction Control: Bi-Directional

- Mass Flow Controllers (MFCs): 2 standard (Clean Compressed Air, O2)

- Flow Rate Range: 0.003 – 50 SLPM ± 3%

- On-Board Pumps: 4 pumps with Bi-Directional Stepper Motors

- Pump Speed Range: 0.2 – 200 RPM

- Pump Head Type: Peristaltic, Flip-Top Pump Heads

- Vessel Compatibility: Eppendorf, Sartorius, and Applikon vessels (Consult your sales rep for specific compatibility)

- Standard Automation & Control Offering: Rockwell™ software with Ethernet communication

- Enclosure Rating: IP-21 Available

- Power Requirements: 120 – 230 VAC, 50/60 Hz, 1200 Watts

More details are available in the technical brochure.

Enhance your bioprocessing with AES Tubing Sets, designed for seamless integration with our Basic Fermentation Benchtop Bioprocess Controller (BPC) units. Featuring high-quality tubing options, including Platinum-Cured Silicone and Thermoplastic Elastomer, these sets deliver reliable performance in critical applications. Each component is assembled and packaged in an ISO 14644-1 Class 7 Clean Room environment, ensuring superior sterility and quality. The tubing sets are sterilized using Gamma Irradiation (27.5-45 kGy), providing unmatched safety and biocompatibility, compliant with USP Class VI and ISO 10993 standards. AES Tubing Sets guarantee exceptional durability and purity, making them the perfect choice for your bioprocessing needs.

- Material Composition: Platinum-cured Silicone, Thermoplastic Elastomer, Polycarbonate, Polypropylene

- Environmental Requirement: ISO 14644-1 Class 7 Clean Room Environment

- Sterilization Method: Gamma Irradiation (27.5-45 kGy)

- Compatibility: Specifically designed for AES Basic Fermentation BPC units and your chosen compatible vessel

- Compliance: USP Class VI, ISO 10993

More details are available in the technical brochure.

The Basic Fermentation Benchtop Bioprocess Controller (BPC) is engineered to meet the stringent requirements of regulated environments. It is GMP compliant and can be configured to support 21 CFR Part 11 compliance, ensuring adherence to electronic records and signatures industry standards.

The AES Tubing Sets designed for the Basic Fermentation BPC are manufactured in an ISO 14644-1 Class 7 Clean Room environment, ensuring high standards of sterility and quality. These sets comply with USP Class VI and ISO 10993 standards, covering critical biocompatibility aspects. This ensures the tubing sets meet biopharmaceutical applications’ essential safety and reliability requirements.

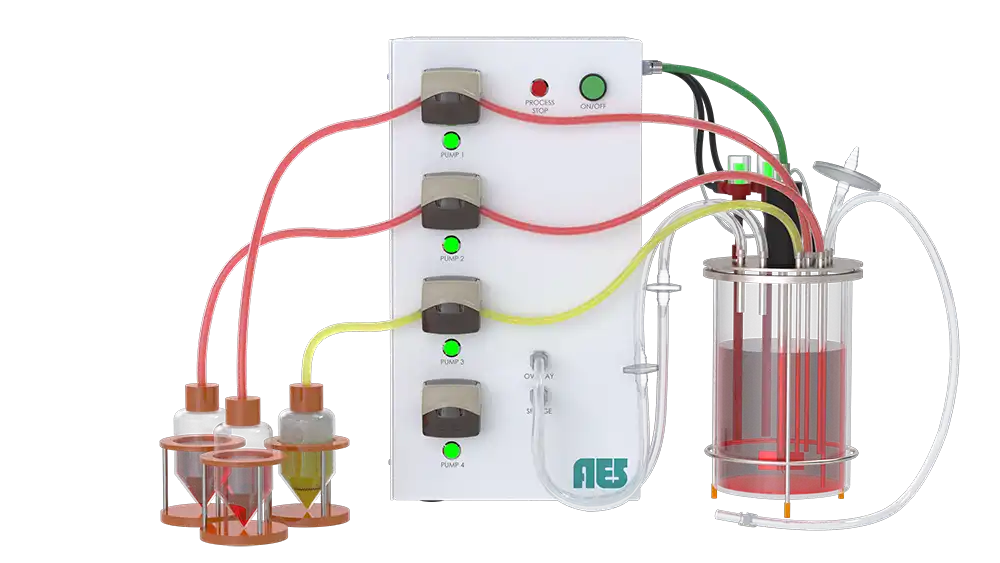

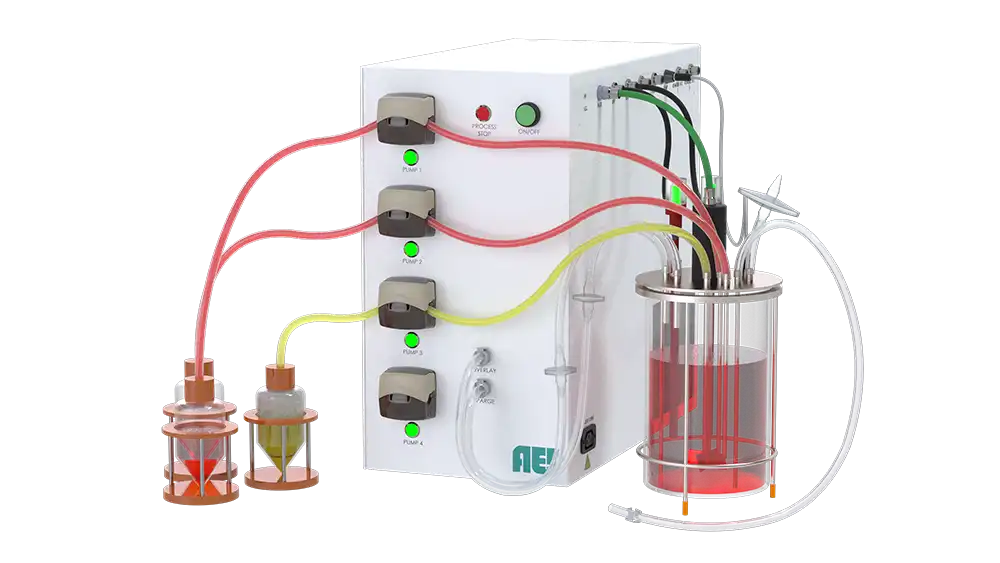

The Basic Fermentation Benchtop BPC System

(4) Integrated Pumps

AES Tubing Set

Compatible Bioreactor Vessel

Process E-Stop and On/Off Buttons

Gas Overlay & Sparge Connections

Agitation Connection, pH, DO, Biomass, CO2/O2, temp sensors, Remote I/Os

External Heating Supply

(4) Integrated Pumps

AES

Tubing

Set

Compatible Bioreactor

Vessel

Process E-Stop and On/Off Buttons

Gas Overlay & Sparge Connections

Agitation Connection, pH,

DO, Biomass, CO2/O2,

temp sensors, Remote I/Os

External Heating Supply

Why Choose AES for Your Fermentation Benchtop Bioprocess Controller?

Customizable for Your Bioprocess Needs

The Basic Fermentation Benchtop Bioprocess Controller can be tailored to meet the specific requirements of your bioprocess. Whether you need custom sizes, configurations, or features, we work closely with you to ensure this rocking bioreactor system aligns with your needs.

Seamless Integration for Your Lab or Facility

The Basic Fermentation Benchtop Bioprocess Controllwe is designed for seamless integration with your DCS. This compatibility allows for easy connection and communication with existing automation and control systems, enabling centralized monitoring and control of your operations.

Aftermarket Services & Training

Comprehensive aftermarket services and training is available to ensure you get the most out of your Mammalian Benchtop Bioprocess Controller. Our team provides ongoing support, maintenance, and training to keep your operations running efficiently and effectively.

Fabricated in the USA

All Bioprocess Controllers are manufactured in the USA, adhering to the highest standards of quality and precision. This ensures reliability and consistency in every unit, providing you with a dependable solution for your bioprocess needs.

Basic Fermentation Benchtop Bioprocess Controller Applications

Fermentation

- Microbial Fermentation

- Vaccine Production

- Recombinant Proteins

- Antibiotic Production

Bioprocessing & Manufacturing

- Upstream Processing

- Batch & Fed Batch Cultures

- Scale-up & Scale-down

Process Monitoring & Optimization

- Real-Time Monitoring

- Process Development

- Automated & Semi-Automated Control

Frequently Asked Questions

Yes, the Basic Fermentation Benchtop BPC is highly customizable to accommodate specific process requirements. Our team collaborates closely with clients to tailor the system, optimizing it for unique cell culture and bioprocessing protocols.

The Basic Mammalian BPC offers more advanced gas control than the Basic Fermentation BPC. The Mammalian BPC features 3 to 4 Mass Flow Controllers (MFCs) that manage clean compressed air (CCA), oxygen (O2), carbon dioxide (CO2), and nitrogen (N2), with nitrogen being an optional configuration. On the other hand, the Fermentation BPC typically includes 1 to 2 MFCs, controlling only CCA and O2, with oxygen as an optional feature.

In addition to gas control, the agitation capabilities also differ. The Mammalian BPC is designed for gentler mixing, offering an agitation speed range of 0 to 600 RPM, ideal for sensitive mammalian cells. Conversely, the Fermentation BPC supports a broader range of agitation, from 0 to 1200 RPM, to accommodate the more vigorous mixing required for fermentation processes.

Absolutely. The Basic Fermentation Benchtop BPC integrates with Rockwell as a standard. However, our engineering team can customize the integration to seamlessly work with your preferred choice of DCS, ensuring compatibility and streamlined operation within your existing automation infrastructure.

Certainly! At AES, we conduct rigorous Factory Acceptance Testing (FAT) to guarantee that all equipment meets our stringent quality standards before it leaves our facility. In addition to FAT, our dedicated Global Service Team can oversee Site Acceptance Testing (SAT) to ensure seamless installation and operation at your site. For more detailed information, please visit our Aftermarket Service page.

Yes, in addition to detailed user manuals, we can provide comprehensive operator training sessions. Our training ensures your team can confidently operate and maintain our equipment, maximizing its performance and longevity.

Yes, we do. Our Global Service Team is unwaveringly dedicated to providing comprehensive aftermarket support to ensure your equipment continues to operate at peak performance. For any issues that cannot be resolved remotely, we guarantee on-site arrival within 48 hours. For more details, please visit our Aftermarket Service page.

Lead times vary depending on the complexity and customization requirements of the equipment. Our sales team can provide specific lead time estimates based on your project timeline and needs.

We can provide references upon request. These documents showcase our successful collaborations and the positive impact of our solutions on our clients’ operations.

Get a Bioprocess Controller that Meets Your Specific Bioprocess Today!