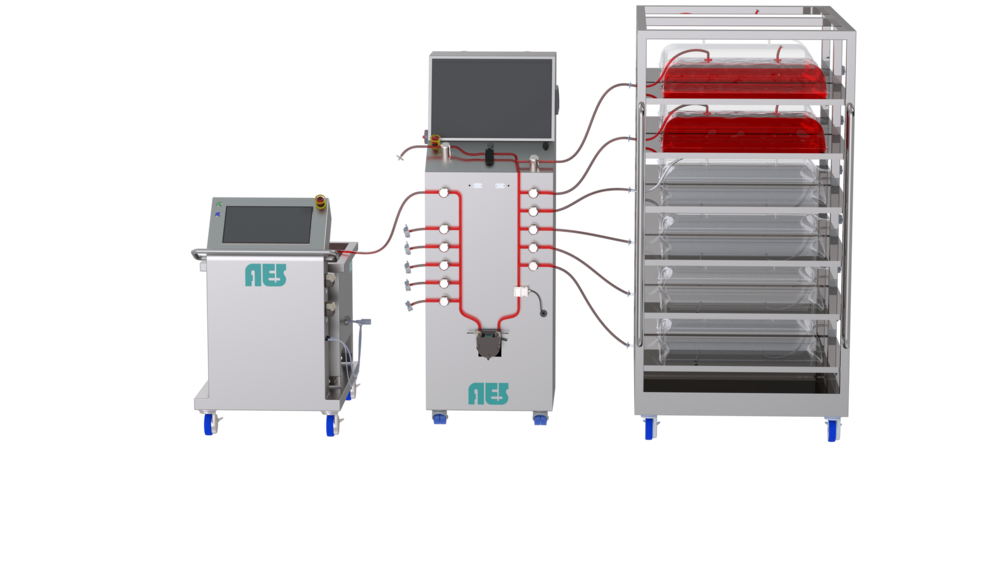

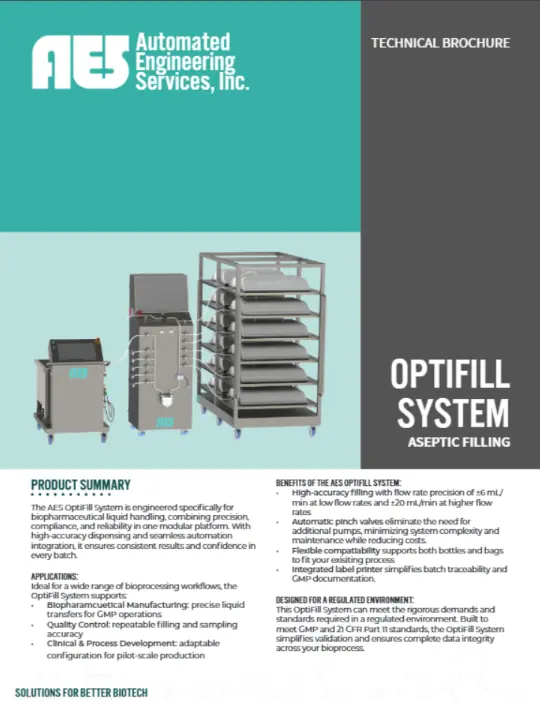

Aseptic Filling System

Optimize Your Aseptic filling Accuracy with the AES OptiFill System

The AES OptiFill System stands as the benchmark in aseptic filling solutions, merging precision engineering with advanced automation to meet the rigorous demands of biopharmaceutical production.

Designed with a deep understanding of bioprocessing challenges, the OptiFill System ensures unmatched accuracy, scalability, and reliability throughout the liquid handling process.

Benefits of the OPTIFill fILL FINISH System:

Unparalleled Precision

Achieve ±5% target filling accuracy and consistent flow management with integrated bi-directional peristaltic pumps and automated pinch valves. The system ensures dependable, repeatable results across diverse production runs.

Seamless Container Integration & Compatibility

With the ability to support your choice of container, including both bags and bottles, the OptiFill System integrates effortlessly into various bioprocessing workflows. This versatility ensures smooth operation and compatibility with both new and existing processes, providing reliable performance tailored to your production needs.

Flexible Scaling Capabilities

Capable of handling filling volumes ranging from 100 mL to 50 L, the automated system is designed to scale with your production needs, from small-scale clinical batches to large-scale commercial runs.

Single-Use Mixer for Enhanced Efficiency

Equipped with a Single-Use Mixer (SUM) that minimizes contamination risk while delivering consistent, homogenous mixing, maintaining product integrity throughout the cycle. This feature offers unparalleled operational flexibility, allowing seamless transitions between different production scales and products.

Advanced Automation & Control

Leverage the power of the Emerson DeltaV control system for seamless operation, or choose a control system that aligns with your facility. Real-time data collection, remote monitoring, and intelligent alarm systems enhance productivity and enable proactive process management, ensuring efficient and reliable operations.

OptiFill System Details & Technical Data

The AES OptiFill System is designed to meet the stringent demands of modern bioprocessing, offering high precision, flexibility, and reliable performance. Engineered with advanced automation and a user-centric approach, it supports diverse production needs with seamless container integration and robust control options.

Liquid Handling Unit (LHU):

- Flow Rate Accuracy:

- ±6 mL/min for low-flow rates (0 – 300 mL/min)

- ±20 mL/min for higher-flow rates (1,000 – 10,000 mL/min)

- Pump Type: Peristaltic, Flip-Top

- Pump Speed Range: 0.2 – 410 RPM

- Pressure Sensors: 2 sensors (-0.7 to 7.5 psig)

- Flow Meter: Clamp-on, 6 – 3,000 mL/min range (for low-flow)

- Filling Volume Range: 100 mL – 50 L

- Target Filling Accuracy: ±5%

Single-Use Mixer (SUM):

- Volume Options: 50 L to 3,000 L

- Mixing Technology: Magnetic Levitation for uniform agitation

- Weight Measurement: Integrated load cells for real-time monitoring

- Temperature Control: RTD sensor, 20°C – 60°C ± 0.15°C

More details are available in the technical brochure.

Ensure seamless, aseptic fluid transfer with AES OptiFill consumables, designed for precision and flexibility in biopharmaceutical manufacturing. Tailored for diverse filling applications, these pre-assembled and sterilized components integrate effortlessly into your system to support smooth, efficient operation.

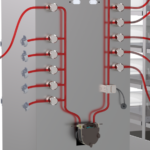

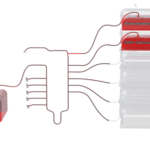

- OptiFill Tubing Set: The OptiFill Tubing Set ensures precise, aseptic fluid transfer by connecting the Single-Use Mixer (SUM), Liquid Handling Unit (LHU), and fill vessels. It’s engineered for flexible flow rate requirements, with high and low application options.

- SUM Bags: Specifically designed for the Single-Use Mixer, these bags maintain product integrity during mixing. The sterile, flexible containment options support various mixing volumes, which is ideal for sensitive applications.

- OptiFill Containers (Bags or Bottles):

The system offers adaptable container options for various liquid volumes. Each container type is designed to meet specific storage requirements, including temperature compatibility down to -80°C, ensuring versatility for various bioprocessing needs.

More details are available in the technical brochure.

The OptiFill System is engineered to meet the stringent requirements of regulated environments. It is GMP compliant and can be configured to support 21 CFR Part 11 compliance, ensuring adherence to electronic records and signatures industry standards.

The OptiFill System

OptiFill Tubing Set

Touchscreen HMI

OptiFill Bags

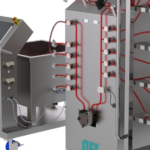

(13) Pinch Valves

Bi-Directional Pump

E-Stop Button

E-Stop Button

Touchscreen HMI

Flow Meter

Liquid Sensor

(2) Pressure Sensors

Unit

Why Choose AES for Your Aseptic Filling System?

Customizable for Your Bioprocess Needs

The AES OptiFill System is designed to meet the unique specifications of your bioprocess. Whether you require specific hardware configurations or seamless control system integration, we work with you to ensure the unit aligns with your aseptic filling process, optimizing for efficiency and accuracy.

Seamless Integration for Your Lab or Facility

Our aseptic filling systems integrate smoothly with your existing infrastructure or preferred control system. The flexibility of our design ensures easy communication with your automation setup, enabling precise monitoring, data acquisition, and control for a streamlined and productive workflow.

Aftermarket Services & Training

AES provides comprehensive support after purchase to ensure you get the most out of your aseptic filling system. From maintenance and troubleshooting to operator training, our team is dedicated to keeping your operations running efficiently and reliably, reducing downtime and ensuring optimal performance.

Fabricated in the USA

Every AES OptiFill System is proudly manufactured in the USA to meet the highest standards of quality and precision. Our systems are engineered to be robust and dependable, delivering consistent results for your bioprocessing needs.

Think AES for your aseptic filling needs—experience precision, scalability, and a partner committed to your success.

OptiFill System Applications

Biopharmaceutical Production

- Monoclonal Antibodies (mAb)

- Biosimilars

- Recombinant Proteins

- Gene Therapy Products

- Cell and Gene-Based Therapies

Quality

Control

- Antiseptic Processing Validation

- Product Sterility Testing

- Batch Consistency

- Final Product Inspection

- Endotoxin Testing

Clinical

Research

- Preclinical Testing

- Phase I and II Clinical Testing

- Vaccine Development

Client spotlight

A partnership in Innovation

Frequently Asked Questions

Below are answers to some of our most common questions about our OptiFill System. Whether you’re looking for detailed specifications, customization options, or insights into how the aseptic filling system fits your process, we’ve got you covered. If you have any further questions, please don’t hesitate to contact our team.

The AES OptiFill System offers a flexible filling volume range from 100 mL to 50 L, designed to meet the diverse needs of bioprocessing workflows and ensure seamless scalability.

Our system is engineered for versatility, compatible with AES OptiFill Bags and bottles, enabling seamless integration into various bioprocessing environments.

The OptiFill System guarantees a target filling rate accuracy of ±5%, providing dependable performance that instills confidence in each process.

Absolutely. The OptiFill System features cleanroom-compatible casters, allowing easy movement and flexibility within your facility.

Our system ensures flow rate accuracy of ±2% for flow rates between 300 and 3,000 mL/min and ±6 mL/min for flows up to 300 mL/min, ensuring reliable outcomes across various applications.

The OptiFill System is integrated with the Emerson DeltaV control system, with customization options available to suit your specific operational preferences.

Certainly! At AES, we conduct rigorous Factory Acceptance Testing (FAT) to guarantee that all equipment meets our stringent quality standards before it leaves our facility. In addition to FAT, our dedicated Global Service Team can oversee Site Acceptance Testing (SAT) to ensure seamless installation and operation at your site. For more detailed information, please visit our Aftermarket Service page.

Yes, in addition to detailed user manuals, we can provide comprehensive operator training sessions. Our training ensures your team can confidently operate and maintain our equipment, maximizing its performance and longevity.

Yes, we do. Our Global Service Team is unwaveringly dedicated to providing comprehensive aftermarket support to ensure your equipment continues to operate at peak performance. For any issues that cannot be resolved remotely, we guarantee on-site arrival within 48 hours. For more details, please visit our Aftermarket Service page.

Lead times vary depending on the complexity and customization requirements of the equipment. Our sales team can provide specific lead time estimates based on your project timeline and needs.

We can provide references upon request. These documents showcase our successful collaborations and the positive impact of our solutions on our clients’ operations.

Start Your Journey to Precision and Efficiency

Take the first step toward enhancing your bioprocessing workflow with an advanced aseptic filling system. Our experts are ready to guide you through a tailored solution that meets your unique operational needs. Complete the form to get your custom quote and see how the AES OptiFill System can elevate your production capabilities.