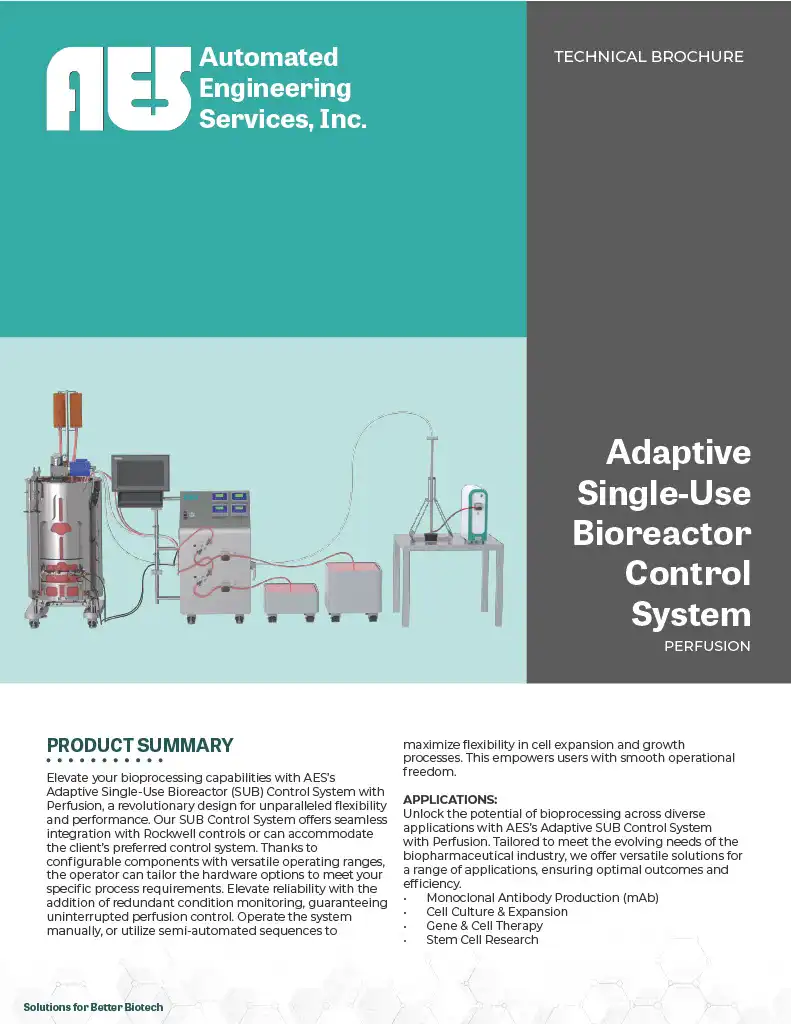

AES Single-Use Bioreactor Control Systems

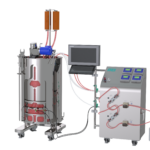

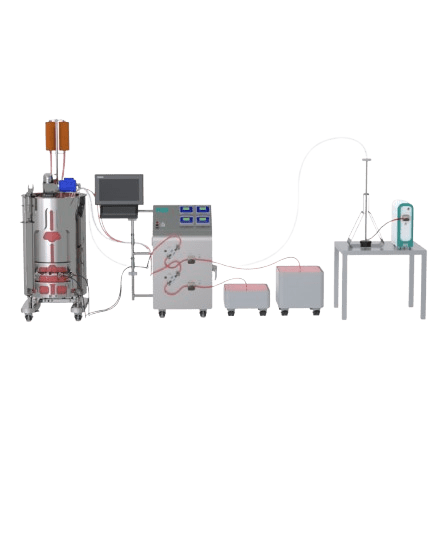

Adaptive Perfusion SUB Control System

The Adaptive Perfusion SUB Control System is a cutting-edge solution that elevates cell culture processes, particularly in single-use bioreactor applications requiring continuous perfusion. Equipped with advanced control capabilities for precise liquid management, gas flow, temperature regulation, and real-time data monitoring, this system ensures optimal performance and process efficiency. Its modular design integrates seamlessly with Rockwell controls or your preferred control platform, offering unparalleled flexibility to meet diverse bioprocessing needs. With features like redundant condition monitoring and ATF control, the system guarantees uninterrupted operations and high throughput, making it ideal for monoclonal antibody production, cell therapy, gene therapy, and stem cell research.

Tailored for the evolving needs of the biopharmaceutical industry, the Adaptive Perfusion SUB Control System enhances efficiency, reduces downtime, and accelerates your time to market—delivering a robust platform built for both process development and commercial-scale manufacturing.

Benefits of the Adaptive Perfusion SUB Control System

Scalability for Commercial Manufacturing

Scale confidently from pilot to production with support for bioreactor volumes from 50L to 500L. This platform grows with your process—minimizing tech transfer risks and avoiding costly revalidation as you move into commercial manufacturing.

Advanced ATF Control for Perfusion

Unlock high-efficiency continuous processing with built-in Alternating Tangential Flow (ATF) control. Maintain healthier, high-density cell cultures while reducing media consumption and maximizing product output in demanding perfusion workflows.

Cost-Effective & Accelerated Time to Market

Speed up your path to commercialization with a system engineered for fast deployment, lower capital investment, and reduced operational complexity—helping you launch therapies faster and with greater cost-efficiency.

Versatile System Integration

Easily integrate with your existing infrastructure, including Rockwell and DeltaV platforms, and a wide array of single-use bioreactor vessels like Thermo Fisher HyPerforma™. The system’s flexible architecture supports evolving process and platform needs.

Enhanced Efficiency & Control

Ensure optimal bioprocess performance with precise control over gas, liquid, and temperature parameters—all managed through an intuitive, user-friendly HMI that empowers operators to maintain consistent, high-quality production conditions.

Adaptive Perfusion Single-Use Bioreator Control System

Details & Technical Data

The Adaptive Perfusion SUB Control System is an advanced bioprocessing solution for single-use bioreactor applications. It delivers precise control over liquid management, gas flow, temperature, and real-time monitoring to optimize cell culture processes. The system’s modular design ensures seamless integration with existing control systems and bioreactor vessels, offering adaptability from process development to full-scale manufacturing.

- Vessel Compatibility: Compatible with Thermo Fisher Hyperforma™ or other preferred bioreactor vessels.

- Gas Control: Equipped with 5 Mass Flow Controllers (MFCs) for precise regulation of gases (CCA, O2, CO2, N2) with configurable flow rates from 0.003 to 50 SLPM.

- Temperature Control: Operates within a range of 5°C to 40°C, with ±0.1°C accuracy, supported by an auxiliary Temperature Control Unit (TCU).

- Liquid Handling: Dual peristaltic pumps and integrated flow meters ensure precise liquid handling, adaptable to various bioprocesses.

- Advanced ATF Control: Optimizes filtration efficiency with bi-directional Mass Flow Controllers (MFCs) that drive the diaphragm pump, ensuring efficient media flow and resource management during continuous perfusion processes.

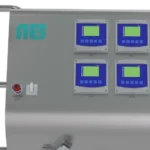

- Automation & Control: Rockwell and DeltaV compatibility with user-friendly HMI for streamlined control and monitoring.

- Scalability: Vessel volumes ranging from 50L to 500L provide flexibility for small-scale and commercial-scale production.

- Compliance: Designed to meet GMP and 21 CFR Part 11 standards, ensuring regulatory adherence and data integrity.

More details are available in the technical brochure.

The Adaptive Perfusion SUB Control System is engineered to meet the stringent requirements of regulated environments. It is GMP compliant and can be configured to support 21 CFR Part 11 compliance, ensuring adherence to electronic records and signatures industry standards.

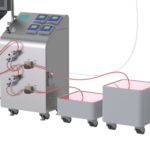

Adaptive Single-Use Bioreator Control System

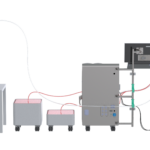

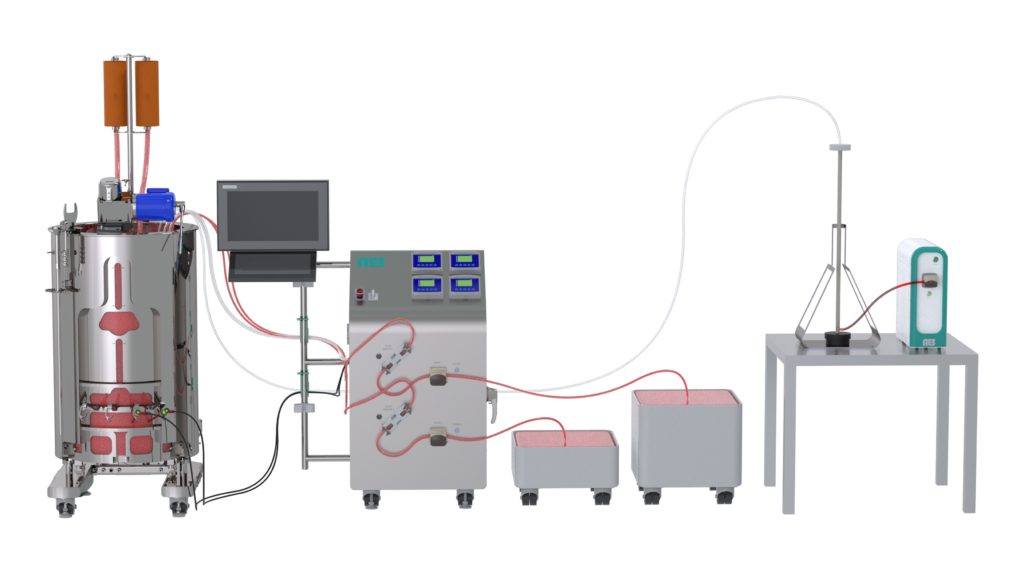

(2) Integrated Pumps

pH & DO Transmitters

E-Stop and On/Off Switch

(2) Flow Sensors Connections

HMI Screen

Side Panel with Connection Access for:

- Pressure

- pH

- DO

- Vent Filter Heater

- Temperature

- Sparge & Overlay

Wheels & Leveling Castors

Bioreactor Control Panel

Wheels & Leveling Castors

Compatiable Single-Use

Bioreactor Vessel

Compatiable ATF Unit

ATF Control Unit

Integrated Pump

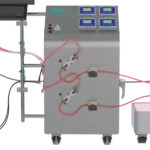

(2) Integrated Pumps

pH & DO Transmitters

E-Stop and On/Off Switch

(2) Flow Sensors Connections

HMI Screen

Side Panel with Connection Access for:

- Pressure

- pH

- DO

- Vent Filter Heater

- Temperature

- Sparge & Overlay

Wheels & Leveling Castors

Bioreactor Control Panel

Compatible

Single-Use

Bioreactor Vessel

Compatiable ATF Unit

ATF Control Unit

Integrated Pump

Why Choose AES for Your Perfusion Single-Use Bioreactor Control System?

Customizable for Your Bioprocess Needs

The Adaptive Perfusion SUB Control System can be tailored to meet the specific requirements of your bioprocess. Whether you need custom sizes, configurations, or features, we work closely with you to ensure this rocking bioreactor system aligns with your needs.

Seamless Integration for Your Lab or Facility

The Adaptive Perfusion SUB Control System is designed for seamless integration with your DCS. This compatibility allows for easy connection and communication with existing automation and control systems, enabling centralized monitoring and control of your operations.

Aftermarket Services & Training

Comprehensive aftermarket services and training is available to ensure you get the most out of your Adaptive Perfusion SUB Control System. Our team provides ongoing support, maintenance, and training to keep your operations running efficiently and effectively.

Fabricated in the USA

All SUB Control Systems are manufactured in the USA, adhering to the highest standards of quality and precision. This ensures reliability and consistency in every unit, providing you with a dependable solution for your bioprocess needs.

Adaptive Perfusion SUB Control System Applications

Cell Culture

- mAb Production

- Vaccine Production

- Recombinant Proteins

- Biosimilars

- Cell-Based Meat

Gene Therapy

- AV

- Gene Replacement

- Gene Editing

- Oncolytic Viruses

Cell Therapy

- CAR-T Therapy

- iPSC

- MSC

- Immune Cell Expansion

Fermentation

- Bacterial Cultures

- Yeast Cultures

- Enzyme Fermentation

- Microbial Fermentation

Perfusion

- Continous Cell Cultures

- Long-Term Cell Expansion

- High-Volume Viral Vector Production

- Lon-Term Immune Cell Expansion

Bioprocessing & Manufacturing

- Media & Buffer Prep

- Upstream Processing

- Process Development

Frequently Asked Questions

Below are answers to some of our most common questions about our Adaptive SUB Control System. Whether you’re looking for detailed specifications, customization options, or insights into how the system fits your process, we’ve got you covered. If you have any further questions, please don’t hesitate to contact our team.

The Adaptive Perfusion SUB Control System is designed to work seamlessly with Thermo Fisher HyPerforma™ vessels. However, the system is highly flexible and can be customized to integrate with a wide variety of single-use bioreactor vessels, ensuring compatibility with your specific process requirements.

Absolutely! The Adaptive Perfusion SUB Control System is highly customizable. Our team works closely with you to tailor hardware, software, and control settings to meet your unique bioprocessing needs, whether you’re focusing on continuous perfusion, high cell density culture, or long-term expansion.

The Adaptive Perfusion SUB Control System integrates with Rockwell as a standard offering. However, we can easily customize the system to integrate with your preferred Distributed Control System (DCS) or Programmable Logic Controller (PLC), ensuring seamless compatibility with your facility’s automation infrastructure.

The Adaptive Perfusion SUB Control System excels at managing critical parameters like liquid flow, gas flow, pH, dissolved oxygen (DO), and temperature, using real-time monitoring and control. The system’s advanced automation ensures your process runs smoothly, optimizing cell growth and media exchange during continuous perfusion.

Yes, it does! Our system includes optional redundant condition monitoring for key process parameters, giving you peace of mind. In the event of unexpected issues, the system continues running to prevent costly downtime and ensure reliable performance.

The system integrates bi-directional Mass Flow Controllers (MFCs) to precisely manage liquid flow and the diaphragm pumps used in ATF (Alternating Tangential Flow) systems, ensuring seamless media exchange during continuous perfusion processes. This guarantees optimal conditions for long-term cell expansion and high-volume production.

Yes, the Adaptive SUB Control System is designed to accommodate scalable bioprocessing. It supports bioreactor volumes ranging from 50L to 500L, allowing you to easily transition from process development to full-scale commercial manufacturing without major system changes.

Absolutely. The Adaptive SUB Control System allows you to customize perfusion parameters, such as media flow rates and ATF cycles, to meet your specific process requirements. The system’s intuitive HMI provides real-time control over key parameters, ensuring flexibility and precision in continuous processes.

The system is optimized for high cell density processes, particularly with its advanced ATF control. This feature enables continuous nutrient supply and waste removal, maintaining optimal culture conditions even as cell density increases, which is critical for maximizing yields in perfusion-based bioprocessing.

Certainly! At AES, we conduct rigorous Factory Acceptance Testing (FAT) to guarantee that all equipment meets our stringent quality standards before it leaves our facility. In addition to FAT, our dedicated Global Service Team can oversee Site Acceptance Testing (SAT) to ensure seamless installation and operation at your site. For more detailed information, please visit our Aftermarket Service page.

Yes, in addition to detailed user manuals, we can provide comprehensive operator training sessions. Our training ensures your team can confidently operate and maintain our equipment, maximizing its performance and longevity.

Yes, we do. Our Global Service Team is unwaveringly dedicated to providing comprehensive aftermarket support to ensure your equipment continues to operate at peak performance. For any issues that cannot be resolved remotely, we guarantee on-site arrival within 48 hours. For more details, please visit our Aftermarket Service page.

Lead times vary depending on the complexity and customization requirements of the equipment. Our sales team can provide specific lead time estimates based on your project timeline and needs.

We can provide references upon request. These documents showcase our successful collaborations and the positive impact of our solutions on our clients’ operations.

Get a SUB Control System that Meets Your Specific Bioprocess Today!