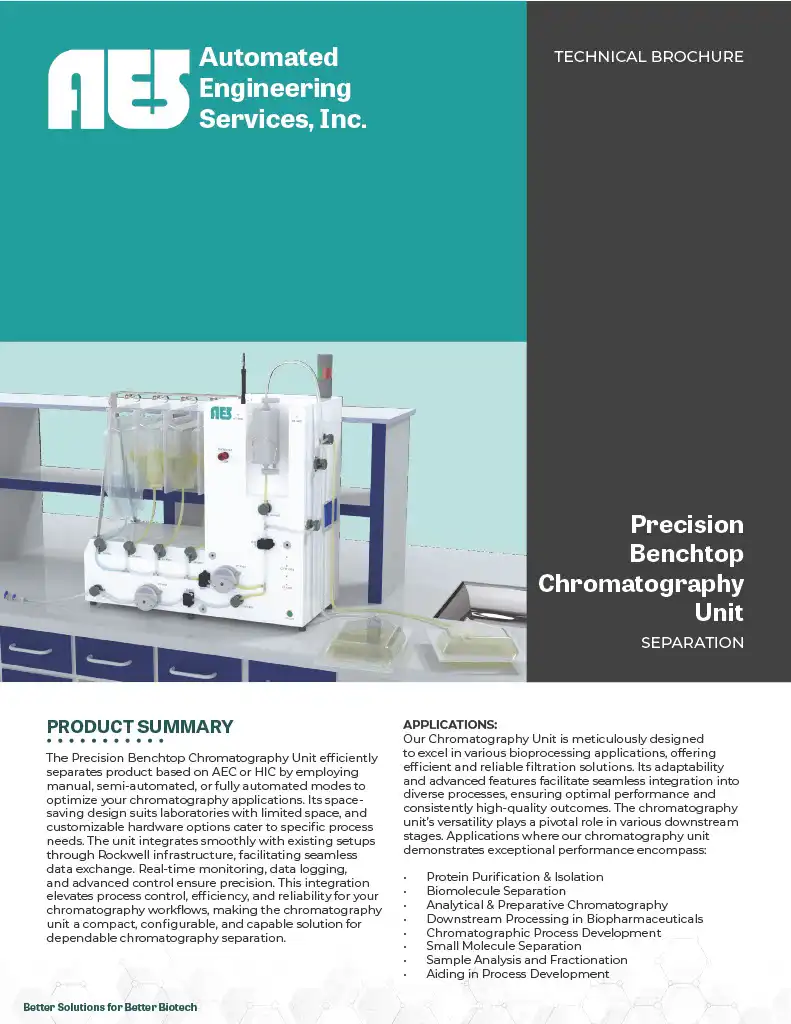

AES Chromatography Systems

Streamline Your Separation Process with the

Precision Chromatography Benchtop Unit

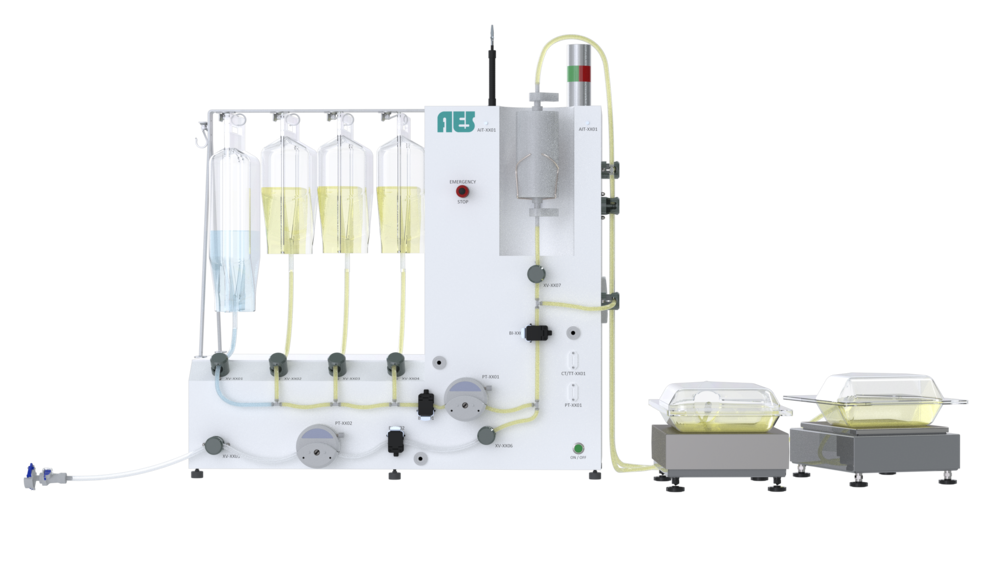

The Precision Chromatography Unit is a compact solution designed to optimize downstream bioprocessing with flexible manual, semi-automated, or fully automated modes. Its bi-directional flow capability enhances process efficiency, making it ideal for various applications such as protein purification and biomolecule separation, while the compact design fits seamlessly into space-constrained labs.

With real-time monitoring and advanced control features, the unit ensures precise and consistent results. Customizable to work with your preferred chromatography columns, it integrates easily into existing setups, offering unmatched flexibility and performance for small to medium-scale operations.

Benefits of the Chromatography System

Achieve consistent, high-purity separations

Integrated sensors and automation enable precise control over elution conditions—empowering users to optimize peak resolution, monitor protein elution in real time, and improve product yield and reproducibility with real-time UV, pressure, and conductivity monitoring.

Adapt to any chromatography workflow

The system works seamlessly with your preferred columns and enables forward or reverse flow, optimizing resin packing, column washing, and diverse separation strategies across different biomolecules.

Safeguard product integrity with continuous, non-invasive air monitoring

Three strategically placed bubble detectors prevent air contamination that can disrupt separations or damage columns—helping you maintain process consistency, protect high-value samples and increase product yield.

Build for today and scale for tomorrow with flexible automation

With Rockwell™ integration as standard and compatibility with your preferred control systems, the unit supports everything from method development to commercial-scale production—ensuring smooth tech transfer and future scalability.

Maximize functionality in tight lab spaces

The unit’s compact benchtop footprint houses all critical hardware and instrumentation, delivering full chromatography power while preserving valuable workspace.

Precision Chromatography Benchtop Unit

Details & Technical Data

The Precision Chromatography Benchtop Unit is designed to streamline bioprocessing with customizable modes—manual, semi-automated, and fully automated. It integrates seamlessly into existing infrastructures, offering flexibility and precision for a wide range of applications, including protein purification and biomolecule separation. Its compact design fits perfectly into labs with limited space, making it a powerful yet space-efficient solution for downstream processing needs.

- Pump Speed Range: 0.2 to 200 RPM, supported by bi-directional stepper motors for precise flow control.

- Flow Rate Capacity: Up to 340 mL/min with customizable tubing sizes (Max ID: 4.8 mm, L/S #25).

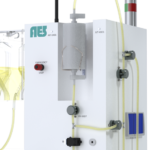

- UV Monitoring: Onboard single-use UV flow cell with 260 nm photometer for real-time protein elution and purity monitoring.

- Conductivity Range: 0 – 100 mS, supported by a single-use conductivity sensor for real-time monitoring.

- Pressure Range: 0 – 60 psi, monitored by a single-use pressure sensor with ±0.15 psi accuracy.

- Bubble Detection: Integrated clamp-on bubble detection system ensures column protection and prevents air contamination.

- Automation & Control: Standard with Rockwell™ automation; customizable to your preferred control system.

- Power Requirements: 120 – 230 VAC, 50/60 Hz, 1200 Watts.

- Dimensions (H x W x D): 41.7 in x 41.3 in x 20.3 in.

More details are available in the technical brochure.

Ensure seamless chromatography workflows with AES precision tubing and flowpath assemblies. Designed to support efficient and sterile operations, our consumables are tailored for various bioprocessing applications, including protein purification and biomolecule separation. Each set is pre-assembled and sterilized, reducing setup time and ensuring optimal performance.

- Flow Path Design: Pre-assembled and customizable to suit various chromatography applications, optimizing fluid transfer.

- Sterilization Method: Gamma irradiation for sterility assurance.

- Bag Options: WFI bags and buffer bags available for fluid management and collection.

The Precision Chromatography Unit is engineered to meet the stringent requirements of regulated environments. It is GMP compliant and can be configured to support 21 CFR Part 11 compliance, ensuring adherence to electronic records and signatures industry standards.

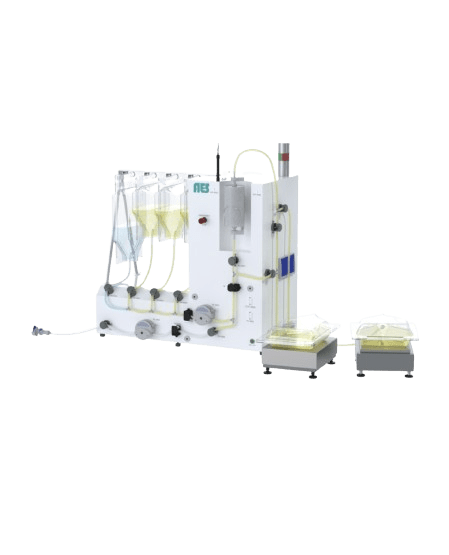

Precision Chromatography Benchtop Unit

Your Preferred Chromatography Column

Buffer Bubble Detector

Sample Bubble Detector

Post Pump Bubble Detector

Conductivity & Temperature Sensor Connection

Buffer Pump

Sample Pump

Waste Bag & Scale

Eluate Bag & Scale

E-Stop Button

AES Flowpath Assembly

WFI Bag

Buffer Bags

Your Preferred Chromatography Column

Buffer Bubble Detector

Sample Bubble Detector

Post Pump Bubble Detector

Conductivity &

Temperature Sensor Connection

Buffer Pump

Sample Pump

Waste Bag & Scale

Eluate Bag & Scale

E-Stop Button

AES Flowpath Assembly

WFI Bag

Buffer Bags

Why Choose AES for Your Chromatography Systems?

Customizable for Your Bioprocess Needs

The AES Precision Chromatography Unit can be tailored to meet the unique specifications of your bioprocesses. Whether you need specific hardware configurations or control system integration, we work with you to ensure the unit seamlessly aligns with your purification and separation processes.

Seamless Integration for Your Lab or Facility

Our chromatography systems integrate smoothly with existing Rockwell™ infrastructure or your preferred control system. This flexibility ensures easy communication with your automation setup, enabling precise monitoring, data acquisition, and control, ensuring a streamlined workflow.

Aftermarket Services & Training

AES provides comprehensive support after your purchase to ensure you get the most out of your chromatography system. From maintenance and troubleshooting to operator training, our team is dedicated to keeping your operations running smoothly and efficiently.

Fabricated in the USA

Every AES chromatography unit is manufactured in the USA to the highest standards of quality and precision. Our systems are designed to be robust and dependable, delivering consistent performance for your bioprocessing needs.

Precision Chromatography Unit Applications

Protein Purification

- Monoclonal Antibody (mAb) Purification

- Recombinant Protein Production

- Biosimilar Purification

- Enzyme Purification

Gene Therapy

- Viral Vector Purification (AAV, Lentivirus)

- Plasmid DNA Purification

- Onocolytic Virus Separation

Cell Therapy

- Cell Harvesting and Purification

- Exosome Purification

- CAR-T Therapy Development

Small Molecule Purification

- API (Active Pharmaceutical Ingredient) Purification

- Natural Product Isolation

- Small Molecule Therapeutics Separation

Process Development & Analysis

- Analytical and Preparative Chromatography

- Process Development for Downstream Applications

- Sample Fractionation and Analysis

Frequently Asked Questions

Below are answers to some of our most common questions about our Precision Chromatography Benchtop Unit. Whether you’re looking for detailed specifications, customization options, or insights into how the system fits your process, we’ve got you covered. If you have any further questions, please don’t hesitate to contact our team.

The AES Precision Chromatography Unit is designed for a wide range of bioprocessing applications, including protein purification, gene therapy (viral vector purification), and small molecule separation. Its flexibility allows it to handle both research and commercial-scale operations with high precision and reliability.

The unit is highly customizable to fit your specific needs. It integrates seamlessly with Rockwell™ automation as standard, but we can customize it to your preferred control system. Additionally, the tubing, flowpath, and other components are configurable to ensure compatibility with your processes.

Yes! Our unit supports manual, semi-automated, and fully automated chromatography processes, providing you with the flexibility to scale as needed. You can start with manual controls and later upgrade to full automation as your bioprocessing needs evolve.

The unit is equipped with real-time sensors for UV, pressure, and conductivity monitoring, providing precise control throughout the chromatography process. This ensures accurate separation and consistency, even during complex purification tasks.

The unit offers real-time monitoring through integrated sensors, including UV, pressure, and conductivity. This allows for precise control of critical parameters and the ability to adjust on the fly, helping you optimize each chromatography run for better yield and purity.

Our non-invasive, clamp-on bubble detection system prevents air from entering the column, which can disrupt the separation process and compromise sample integrity. This feature protects both the column and your valuable product, ensuring the highest yield and purity possible.

Absolutely. The unit is designed with ease of integration in mind. Its compact footprint and customizable design allow it to fit into a variety of lab spaces. Plus, we provide full support during installation, and our automation makes it easy to operate, even for less experienced users.

Certainly! At AES, we conduct rigorous Factory Acceptance Testing (FAT) to guarantee that all equipment meets our stringent quality standards before it leaves our facility. In addition to FAT, our dedicated Global Service Team can oversee Site Acceptance Testing (SAT) to ensure seamless installation and operation at your site. For more detailed information, please visit our Aftermarket Service page.

Yes, in addition to detailed user manuals, we can provide comprehensive operator training sessions. Our training ensures your team can confidently operate and maintain our equipment, maximizing its performance and longevity.

Yes, we do. Our Global Service Team is unwaveringly dedicated to providing comprehensive aftermarket support to ensure your equipment continues to operate at peak performance. For any issues that cannot be resolved remotely, we guarantee on-site arrival within 48 hours. For more details, please visit our Aftermarket Service page.

Lead times vary depending on the complexity and customization requirements of the equipment. Our sales team can provide specific lead time estimates based on your project timeline and needs.

We can provide references upon request. These documents showcase our successful collaborations and the positive impact of our solutions on our clients’ operations.

Get Started with Your Custom Chromatography Solution Now